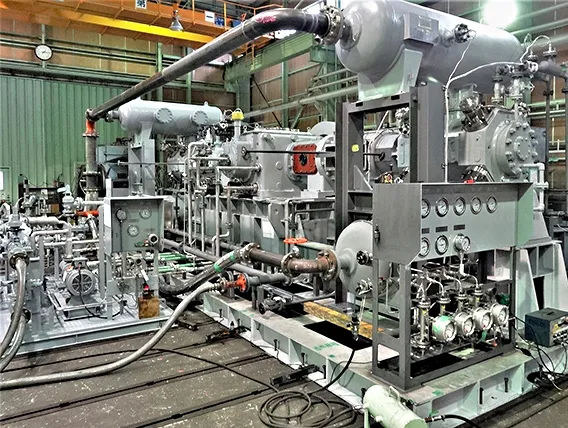

Consistent and integrated process through casting, processing, assembly of the parts, outgoing inspection to shipment of the machines is done in-house. We take responsibility for whole step of the process and commit to deliver the highest quality products to convince the customer.

We cast and manufacture machine parts in our own factory (Yamaguchi 3rd Factory).

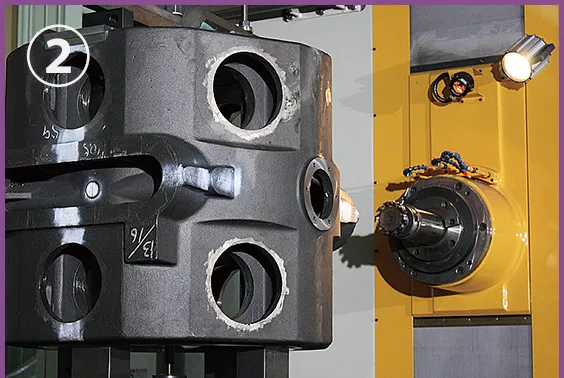

Precision machining by a machining center.

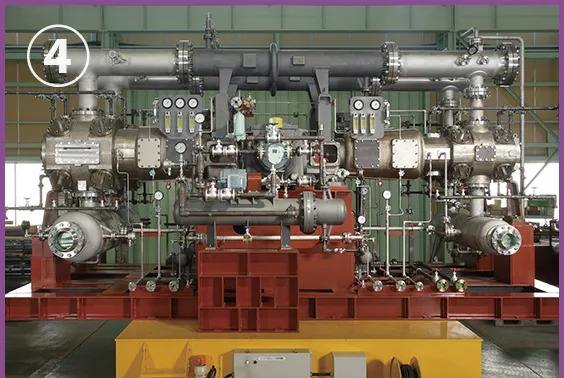

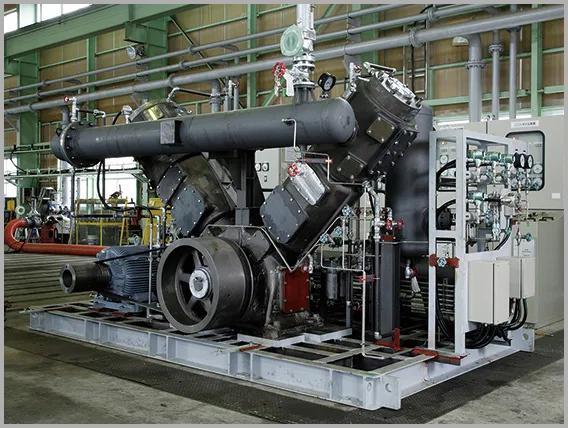

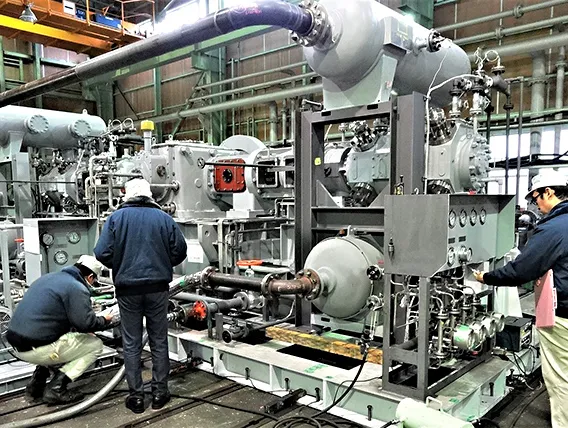

Assembly process based on our well experienced skill and advanced technology.

Forward to Inspection process after assembly.

Only the products which passed severe inspections can be called as the brand of MIKUNI Products.

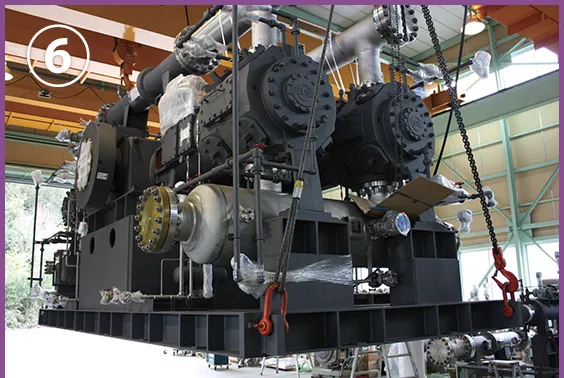

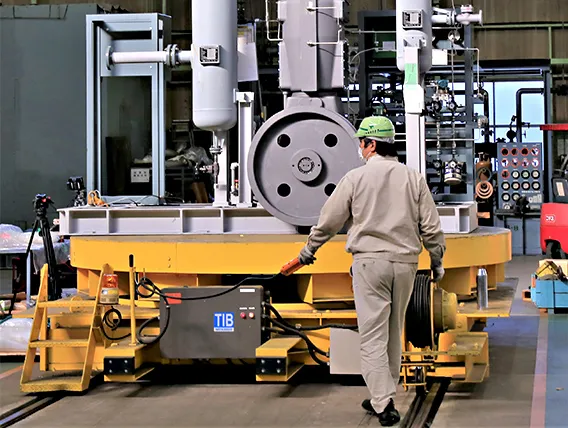

After completed the horizontal opposed compressor, it will be handled with the utmost care and shipped to the customer.

Please feel free to contact us for any request you have about compressors. As the whole MIKUNI GROUP, we provide the best solutions for all of your required compressor.

We are promoting advanced resserch and development to create appropriate compressor which is suitable to change of industrial structure. We merge long experienced know-how and advanced technology to realize the breakthtough for dream of next generation.

Our job starts from listening the voice for purpose of usage and request for our products from customer. We always prioritize our customers' satisfaction and devote to respond to any demand, no matter how diverse or advanced. We promise to provide you with reliable service.

We make sure that you are satisfied with our proposal through a series of meetings, and only then designing the products will be started. Utilizing our large number of experience of delivery in the past and experience-based knowledge, we achieve high cost-performance.

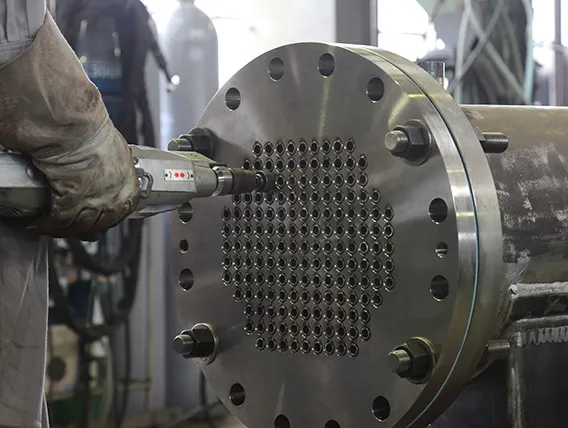

Starting with casting of parts, the entire process including precision machining of cylinders, can manufacturing of pressure vessels and heat exchangers, and assembly work, is done within our group companies. Therefore, we are able to realize high quality MIKUNI-brand products at reasonable cost with short delivery time.

After assembly, we conduct a thorough in-house inspection for all the products, and then a performance inspection with witness of the customer. The products that passed these inspections go through the coating process and a pre-shipment inspection, and are finally shipped to customers in Japan and many of other countries.

MIKUNI’s craftsmanship does not end at the shipment or installation of our products. In order to make sure that our products present optimal performance at all times, we provide maintenance service with our team of customer service engineers and can quickly respond to a request of parts replacement.。

Skillful casting technology with long experience offers high quality products.

Molding

Tooling

Pouring

Design and Manufacturing of Pressure Vessel and Heat Exchanger which is main component of compressor.

Manufacturing of Heat Exchanger

Welding

Welding

Equipment at factory

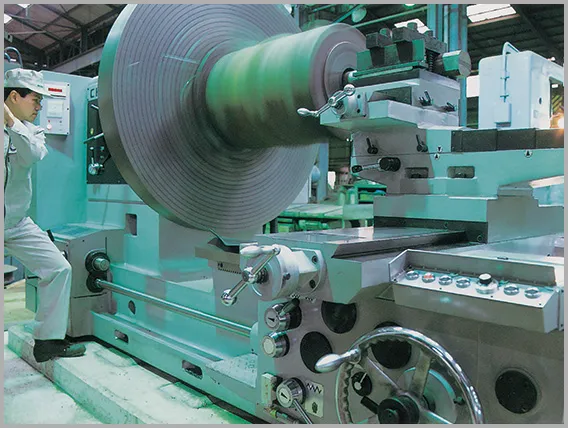

Lathing Machine to lathe cylinder

Machining Center and Cylinder machining

Assembly is the most critical essence for the compressor. We pay our best attention for the assembly including hand operation.

Repeated check for details. Inspection eyes becomes severer during the witness inspection.

Trial Run Inspection room

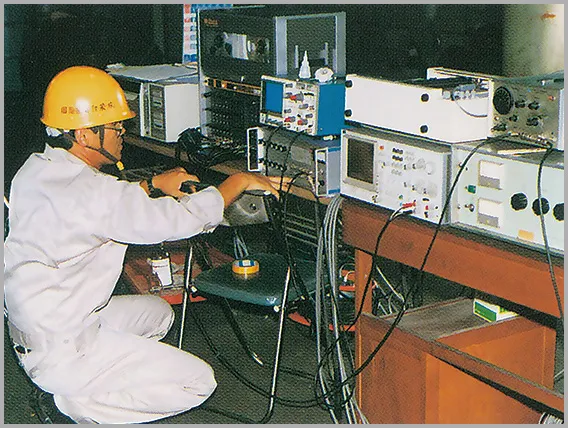

Trial Run Inspection

Vibration analyzing test

Painting is finishing process. Compressor is delivered to the customer after the outgoing inspection.

Painting

Transportation

Shipment