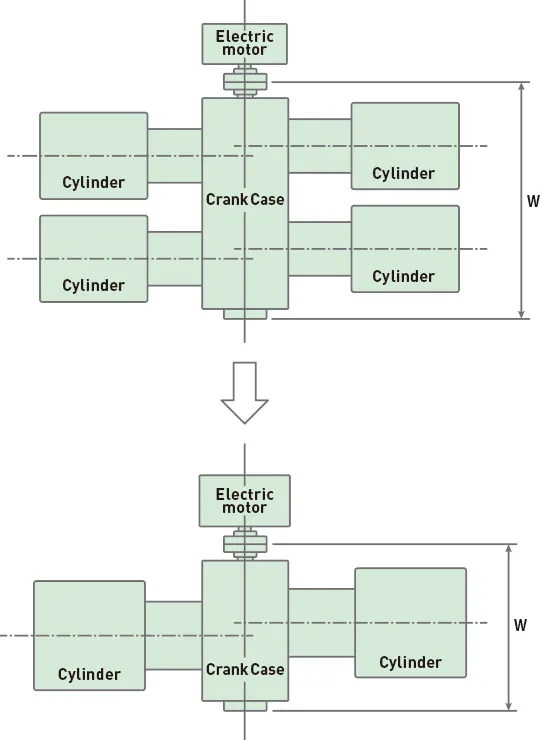

Based on current trend of market, industries and technology, we examined Quality Goal, Production Engineering, Production Equipment and Manufacturing Cost. For example, so far 750kw class compressor had two axis but newly one axial two cylinder high load high output model was developed and production for them is prepared.

Compactification: Cylinder is reduced from 4 to 2 for two axis design. Development of high load high out put crank case realizes compact shape. It makes smaller installation space and reduce the number of parts.

Cost Advantage: To compactify compressor lead to reduce cost of products and installations at the site.

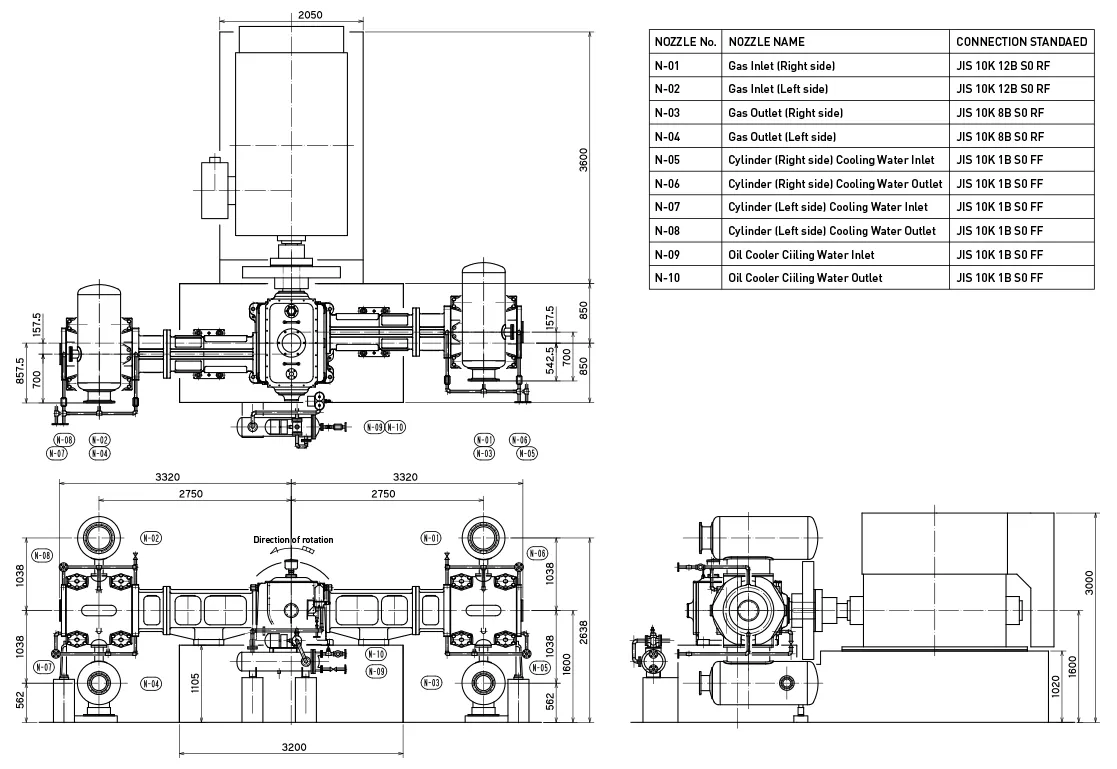

| Case Type | One Axial Two Cylinder |

|---|---|

| Power | Maximum Power 900kW Normal Power 750 kW |

| Designed rotation speed | 500min-1 |

| Maximum Cylinder Diameter | φ700mm |

| Piston Rod Diameter | φ65mm |

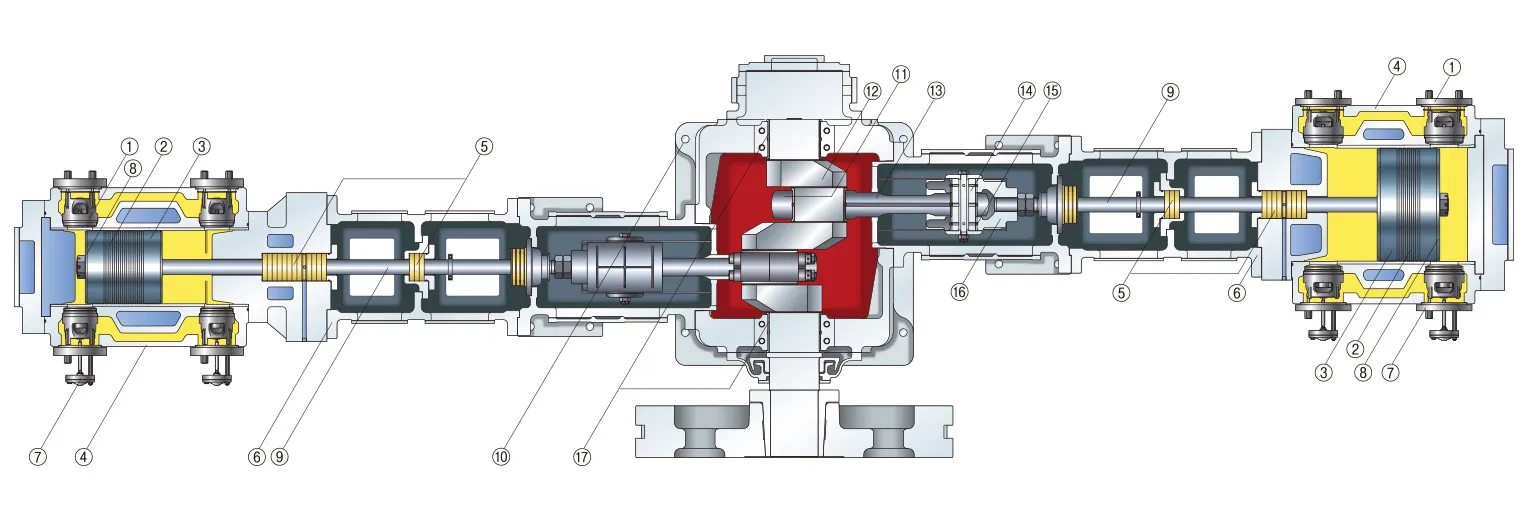

Please refer to outline drawing (General Arrangement) here.

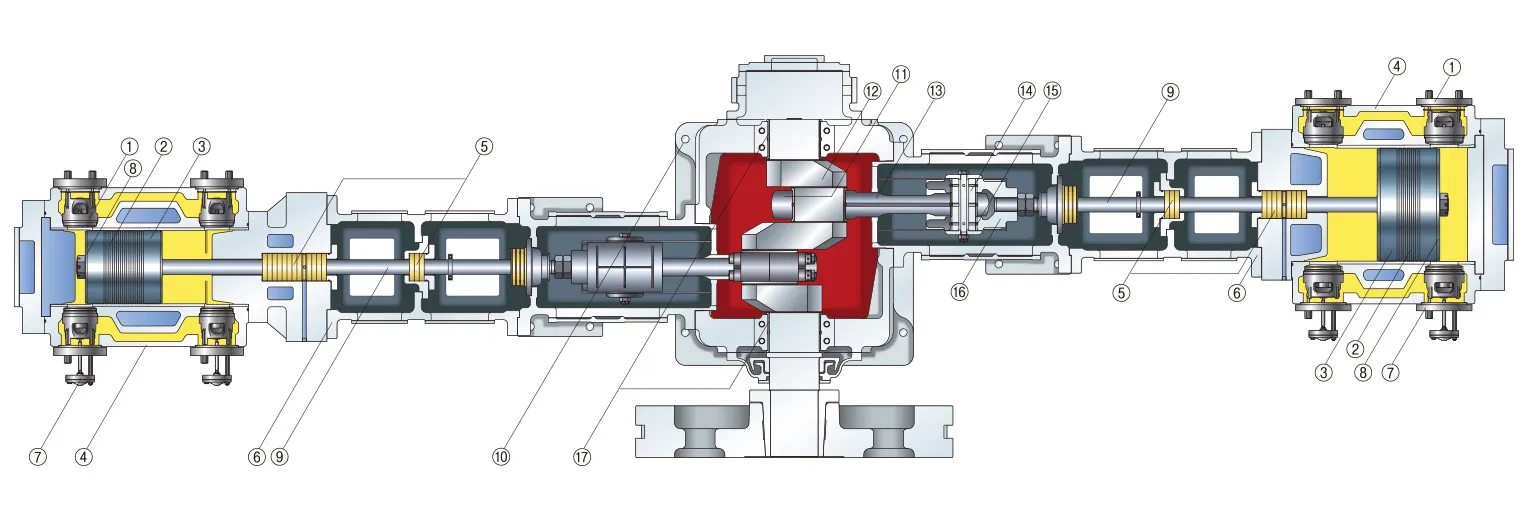

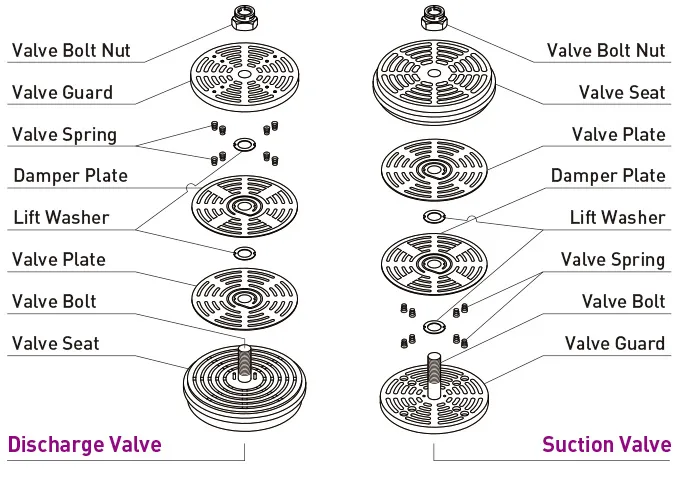

| ① Discharge Valve | ⑦ Suction Valve | ⑬ Connecting Rod |

| ② Piston Ring | ⑧ Piston | ⑭ Crosshead Pin |

| ③ Rider Ring | ⑨ Piston Rod | ⑮ Crosshead Pin Metal |

| ④ Cylinder | ⑩ Crank Case | ⑯ Crosshead |

| ⑤ Gland Packing | ⑪ Crank Pin Metal | ⑰ Main Metal |

| ⑥ Distance Piece | ⑫ Crank Shaft |

| ① Discharge Valve | ⑩ Crank Case |

| ② Piston Ring | ⑪ Crank Pin Metal |

| ③ Rider Ring | ⑫ Crank Shaft |

| ④ Cylinder | ⑬ Connecting Rod |

| ⑤ Gland Packing | ⑭ Crosshead Pin |

| ⑥ Distance Piece | ⑮ Crosshead Pin Metal |

| ⑦ Suction Valve | ⑯ Crosshead |

| ⑧ Piston | ⑰ Main Metal |

| ⑨ Piston Rod |

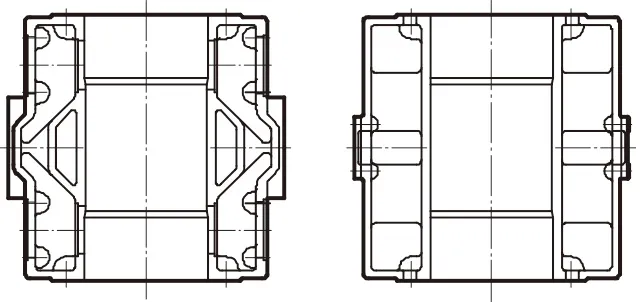

Cylinde has multiple structuire which is consists of gas path and water path. The material of cylinder is changed to FC, FCD,SCS, SCF and others depend on the type of gas to be compresed and pressure. Also cylinder liner type is manufactured.

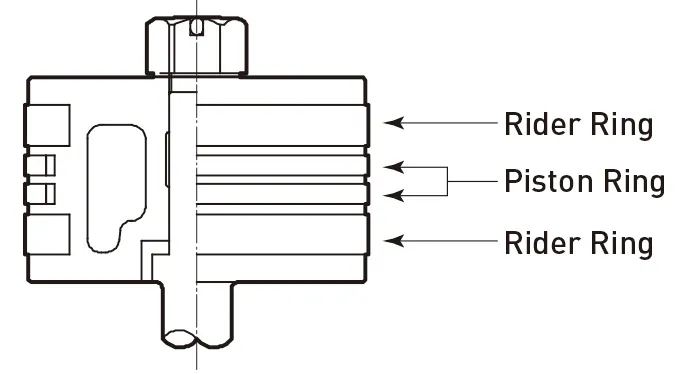

Piston ring is made of self-lubricating materials such as carbon and PTFE. The rider ring prevents metal contact between the piston and cylinder.

Cylinder valve has high durability and reliability because of high frequency of open and close fuction which is combinated to reciprocating movement of pisoton and have to stand severe condition like exposing ompressed gas with high temperature.

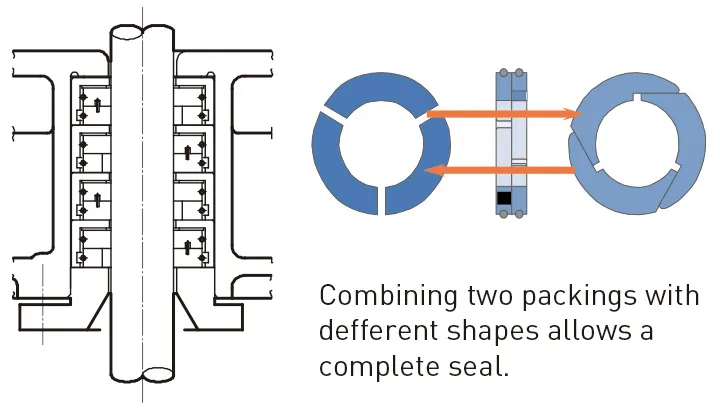

Gland packing prevents leakage of compressed gas from the lower part of the cylinder along the piston rod. Like piston ring, this is made of self-lubricating materials including carbon and PTFE.